Introduction

In the world of printing, the environmental impact of inks is a crucial consideration. The solvent used in printing inks has long been a topic of concern due to its potential harm to both human health and the planet. As a result, there has been a growing interest in exploring water-based inks as an eco-friendly alternative.

The Environmental Impact of Printing Inks

Printing inks, essential for creating vibrant images, can have a hidden environmental cost. Here's how they contribute to air pollution and health risks:

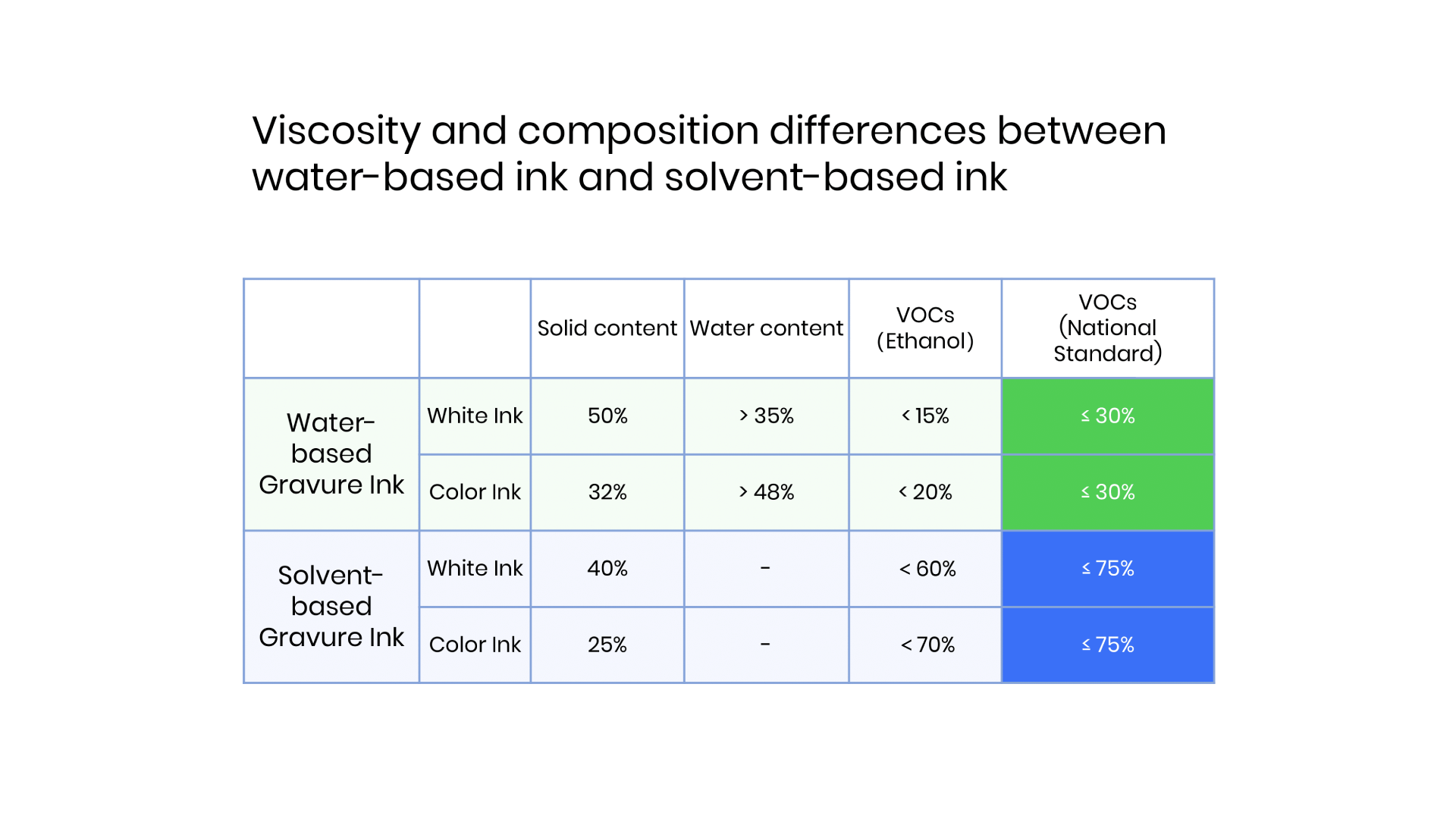

- Emission of Volatile Organic Compounds (VOCs): Traditional inks often use petroleum-based solvents, which release high levels of VOCs during printing. These VOCs pollute the air, creating health risks for printing press workers and anyone nearby.

- Unpleasant Odors and Health Concerns: The strong odors associated with solvent-based inks directly result from VOC emissions. This can cause discomfort and potential long-term health problems for those exposed.

- Air Quality Issues: VOCs don't just linger as unpleasant smells. They contribute to the formation of ground-level ozone and smog, further deteriorating air quality and impacting public health.

While printing inks are vital in communication and design, choosing eco-friendly alternatives and minimizing printing can significantly reduce their environmental impact.

Understanding Solvent-Based Inks

Solvent-based inks are formulated with organic solvents such as ethyl acetate or toluene, which help dissolve the pigments and binders before application onto various substrates. These solvents evaporate during drying, leaving behind a durable and vibrant ink film.

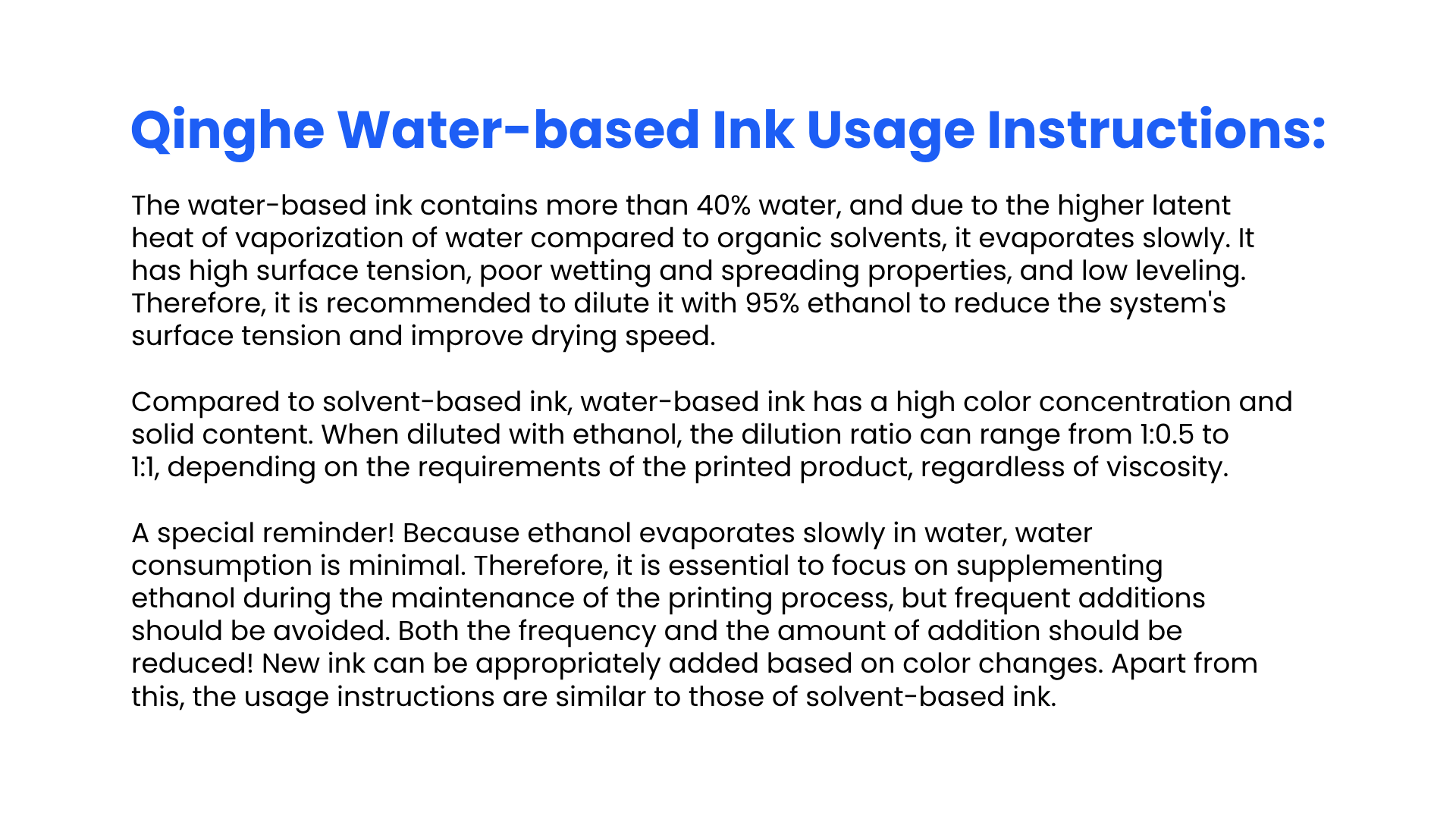

Water-based inks, on the other hand, use water as a solvent instead of organic solvents. This makes them a more environmentally friendly option compared to solvent-based inks. Using water as a solvent also means that water-based inks have lower levels of volatile organic compounds (VOCs), making them safer for both the environment and human health. Additionally, water-based inks are easier to clean and have less odor than solvent-based counterparts.

Exploring Water-Based Inks

On the other hand, water-based inks utilize water as their primary solvent, significantly reducing VOC emissions and environmental impact. These eco-friendly alternatives are gaining popularity due to their lower toxicity and improved safety for workers handling them.

Now that we have set the stage for understanding the environmental impact of printing inks and introduced the concept of solvent-based vs. water-based options let's delve deeper into each aspect to make informed choices for sustainable printing solutions.

Environmental Impact

When it comes to the environmental impact of printing inks, the choice of solvent used plays a crucial role. Solvent-based inks traditionally use volatile organic compounds (VOCs) as the ink solvent, which can contribute to air pollution and harm human health and safety.

Reducing VOC Emissions

To address this issue, many companies are now turning to alternative ink solvents that help reduce VOC emissions. These solvents are designed to minimize the release of harmful chemicals into the atmosphere, making them a more environmentally friendly option for printing applications.

In addition to reducing VOC emissions, alternative ink solvents also offer improved safety for printing industry workers. By minimizing harmful chemicals, these solvents help create a healthier work environment, reducing the risk of exposure to toxic substances. This benefits the employees and contributes to a more sustainable and responsible business operation.

Minimizing Health and Safety Risks

Furthermore, by using solvent-based inks with lower VOC emissions, businesses can also prioritize the health and safety of their workers. Minimizing exposure to hazardous chemicals is essential for creating a safe working environment and reducing potential risks associated with traditional solvent ink pads.

Additionally, using solvent-based inks with lower VOC emissions can also contribute to lowering businesses' environmental footprint. By reducing the release of volatile organic compounds into the atmosphere, companies can minimize air pollution and its harmful effects on the environment. This proactive approach aligns with sustainability goals and demonstrates a commitment to responsible business practices.

Lowering Environmental Footprint

Companies can significantly lower their environmental footprint by transitioning from traditional solvent-based inks to eco-friendly alternatives. This shift benefits the planet and aligns with consumer demand for sustainable products and practices.

Performance

When it comes to performance, solvent-based inks have long been known for their exceptional print quality and color vibrancy. The solvents in printing inks help create sharp, vivid images that stand out on various substrates. This makes solvent ink the top choice for applications where color accuracy and vibrancy are crucial.

Print Quality and Color Vibrancy

Solvent ink is formulated with strong solvents that evaporate quickly, leaving behind a high concentration of pigments. This results in prints with rich, deep colors and excellent image clarity. Whether it's for outdoor signage or indoor displays, solvent-based inks deliver stunning print quality and color vibrancy that capture attention.

Additionally, solvent-based inks offer superior adhesion to various substrates, including vinyl, canvas, and other materials commonly used for signage and displays. This ensures that the prints will stay securely in place without peeling or fading, even in harsh outdoor conditions. The durability of solvent ink prints makes them a reliable choice for long-term use, providing businesses with cost-effective marketing materials that can withstand the elements.

Adhesion and Durability

One of the key advantages of solvent-based inks is their superior adhesion and durability. The ink solvents penetrate the substrate, creating a strong bond that resists fading, scratching, and weathering. This makes solvent ink an ideal choice for applications that require long-lasting prints, such as vehicle wraps, outdoor banners, and industrial labels.

Moreover, solvent-based inks offer flexibility for different applications due to their ability to adhere to various substrates, including plastics, vinyl, and metal. This versatility makes them suitable for various industries, from automotive to retail. Whether it's creating eye-catching point-of-purchase displays or durable floor graphics, solvent inks can meet the demands of diverse printing needs.

Flexibility for Different Applications

Solvent-based inks offer versatility across various applications due to their ability to adhere to various substrates. From vinyl and plastics to fabrics and metals, these inks provide the flexibility for diverse printing needs. Whether for packaging materials or promotional items, solvent-based inks can easily adapt to different surfaces.

Solvent-based inks can adhere to various substrates and offer excellent durability, making them ideal for outdoor applications. Whether it's a vinyl banner exposed to the elements or a promotional item that will be handled frequently, these inks can withstand wear and tear without compromising the quality of the print. This durability ensures that the printed materials maintain their vibrant colors and sharp images for an extended period, providing long-lasting impact and value.

Now you better understand how solvent-based inks excel in print quality, color vibrancy, adhesion, durability, and flexibility across different applications!

Cost Considerations

When considering the cost of printing inks, it's important to weigh the initial investment against long-term savings. Solvent-based inks typically require a higher initial investment due to the solvents used in their composition. However, they often offer long-term savings through increased efficiency and reduced waste.

Initial Investment vs Long-Term Savings

Solvents in printing inks can contribute to higher initial costs, as these solvents are often more expensive than water-based alternatives. However, solvent-based inks are known for their durability and adhesion, which can lead to long-term savings by reducing the need for frequent reprints and replacements.

While the initial investment in solvent-based inks may be higher, the long-term savings can also be attributed to the reduced need for maintenance and storage costs. Solvent-based inks are less prone to smudging and fading, meaning there is less need for ongoing maintenance to keep printed materials looking fresh and professional. Additionally, solvent-based inks' durability means they can withstand various environmental conditions, reducing the need for specialized storage solutions.

Maintenance and Storage Costs

In addition to the initial investment, it's important to consider maintenance and storage costs associated with solvent-based inks. Proper ventilation systems and equipment maintenance are essential for ensuring the safe handling of ink solvents, which can incur additional expenses. Furthermore, storing solvent-based inks requires careful consideration of flammability and safety measures.

Additionally, the use of solvent-based inks may also require companies to invest in specialized disposal methods to comply with environmental regulations. This can add to the overall maintenance costs and require ongoing monitoring to ensure local and federal regulations compliance. Failure to adhere to these regulations can result in costly fines and damage to a company's reputation, making it essential for businesses to factor in these regulatory compliance expenses when considering solvent-based inks.

Regulatory Compliance Expenses

Regulatory compliance expenses should also be factored into the overall cost considerations when using solvent-based inks. Due to the volatile organic compounds (VOCs) present in ink solvents, businesses may incur costs related to environmental permits, emissions monitoring, and compliance with air quality regulations.

Additionally, businesses using solvent-based inks may face waste disposal and handling costs. Disposing ink waste containing VOCs requires special treatment and can incur additional expenses for proper disposal methods. Furthermore, businesses may need to invest in specialized equipment or technologies to minimize the release of VOCs into the environment, adding to the overall regulatory compliance expenses.

Application Versatility

Solvent-based inks offer excellent adhesion and durability for flexible packaging and labels, making them ideal for various substrates such as plastics, films, and foils. Their ability to withstand heat and moisture makes them a top choice for food packaging, ensuring vibrant colors and high-quality prints that meet regulatory standards.

Flexible Packaging and Labels

Solvent-based inks are widely used in flexible packaging and labels due to their superior performance on non-porous materials like polyethylene and polypropylene. Their fast-drying properties make them suitable for high-speed printing, resulting in sharp images with exceptional color vibrancy that stand out on store shelves.

In-Print and Compounding

Solvent-based inks offer the versatility needed for various industrial uses in in-print and compounding applications. Whether printing on metal or composite materials, their compatibility with different substrates allows for seamless integration into manufacturing processes, providing durable markings that withstand harsh environmental conditions.

Compatibility with Different Substrates

Solvent-based inks excel in compatibility with a wide range of substrates, from paper to plastic to metal. Their ability to adhere to diverse surfaces makes them the go-to choice for manufacturers looking for reliable ink solutions that deliver consistent results across different materials.

Qinghe Chemical's Commitment to Environmental Innovation

Understanding the environmental impact of different types of ink solvents is crucial for making informed choices for sustainable printing. As the industry moves towards eco-friendly solutions, the future of printing lies in water-based inks that offer a reduced environmental footprint and lower VOC emissions. With a commitment to environmental innovation, Qinghe Chemical is leading the way in providing high-quality, sustainable ink solutions for the printing industry.

Making Informed Choices for Sustainable Printing

By educating ourselves about solvent used in printing inks and their impact on the environment, we can make more conscious decisions when choosing ink solutions. It's essential to consider print quality and performance and the long-term environmental effects of our choices. With a focus on reducing VOC emissions and minimizing health risks, water-based inks are proving to be a more sustainable option for the future.

The Future of Eco-Friendly Printing Solutions

As technology advances and consumer demand for eco-friendly products grows, the future of printing lies in innovative, environmentally friendly solutions. Water-based inks are gaining traction as they offer vibrant colors, excellent adhesion, and durability while significantly reducing their environmental impact. By embracing these eco-friendly options, we can pave the way for a more sustainable future in the printing industry.

Qinghe Chemical is dedicated to developing cutting-edge ink solutions prioritizing sustainability without compromising performance. With a focus on reducing solvent used in printing inks and lowering VOC emissions, their water-based ink products are leading the way towards a greener future for printing. Their commitment to environmental innovation sets them apart as leaders in providing high-quality, sustainable ink solutions.

In addition to its focus on reducing solvent and VOC emissions, Qinghe Chemical is also dedicated to minimizing waste in producing and distributing its ink solutions. Implementing efficient manufacturing processes and sustainable packaging options can reduce their environmental impact throughout the entire product lifecycle. This commitment to waste reduction further solidifies their position as industry leaders in providing environmentally conscious ink solutions.