Introduction

Flexographic printing inks have made great strides in sustainable printing. With advancements in water-based flexographic inks and innovations in UV inks for flexo printing, the industry is witnessing a rise in demand for eco-friendly solutions. The impact of water-based flexographic printing inks is undeniable, as they offer a more sustainable and environmentally friendly option for printers and manufacturers.

The Evolution of Flexographic Printing Inks

The evolution of flexographic printing inks has been remarkable, with a shift towards more sustainable and eco-friendly options. Flexographic ink manufacturers have been developing water-based ink for flexo printing, reducing environmental impact and offering high-quality print results. This evolution has paved the way for a more sustainable future in the flexo ink industry.

The Role of Flexographic Printing Inks in Sustainable Printing

Flexographic printing is making strides toward sustainability, with UV inks offering several advantages:

- Reduced Energy Consumption: UV inks cure instantly when exposed to ultraviolet light, eliminating the need for drying ovens that consume significant energy.

- Minimized Waste: Faster curing times with UV inks lead to less waste as fewer press stops are required for drying, reducing overall material usage.

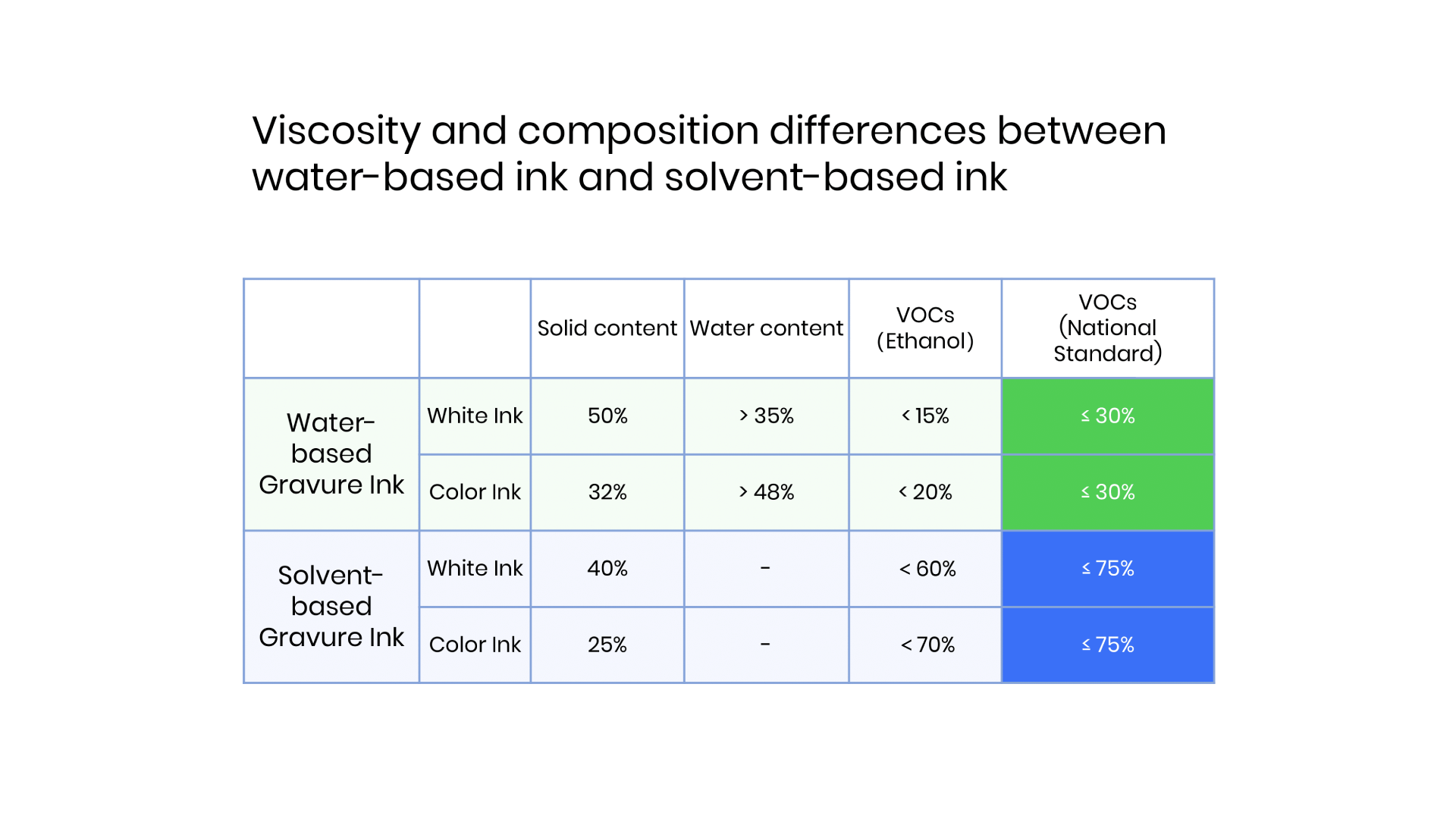

- Lowered VOC Emissions: UV inks typically contain lower levels of volatile organic compounds (VOCs) than traditional solvent-based inks, improving air quality.

By partnering with environmentally friendly flexographic ink suppliers who prioritize sustainable practices, printing businesses can meet the growing demand for eco-friendly solutions and contribute to a greener printing industry.

The Impact of Water-Based Flexographic Printing Inks

The impact of water-based flexographic printing inks cannot be overstated, as they offer numerous benefits for printers and the environment. These eco-friendly options reduce emissions and waste while maintaining high print quality, making them ideal for those seeking to minimize their carbon footprint. As the industry prioritizes sustainability, water-based flexographic ink is poised to play an increasingly important role.

The Rise of Flexographic Printing Inks

With the increasing focus on sustainability, the flexographic ink industry has witnessed significant advancements in water-based flexographic inks. These eco-friendly inks offer a viable alternative to traditional solvent-based inks, reducing environmental impact and promoting sustainable printing practices. As more companies prioritize green initiatives, the demand for water-based ink for flexo printing continues to rise, driving innovation and development within the flexographic ink industry.

Advancements in Water-Based Flexographic Inks

Water-based ink for flexo printing has seen remarkable progress in recent years, with flexographic ink suppliers and manufacturers investing heavily in research and development to improve performance and quality. These advanced formulations offer excellent printability and color vibrancy and deliver superior adhesion and resistance properties, making them a preferred choice for various packaging applications. The versatility of water-based flexographic inks makes them an ideal solution for meeting the diverse needs of the packaging industry while aligning with sustainable printing objectives.

In addition to their sustainability and performance benefits, water-based flexographic inks offer faster drying times than traditional solvent-based inks. This increases production efficiency and reduces energy consumption, making them a cost-effective choice for packaging manufacturers. Furthermore, the low volatile organic compound (VOC) content of water-based inks contributes to a healthier work environment for printing operators and aligns with regulatory requirements for air quality standards.

Innovations in UV Inks for Flexo Printing

In addition to water-based options, innovations in UV inks for flexo printing have also contributed to the rise of the flexographic ink industry. UV-curable inks offer fast curing times, enhanced durability, and high-quality results, making them suitable for many substrates and printing applications. With their ability to reduce energy consumption and emissions, UV inks have gained traction as an eco-friendly alternative within the flexographic printing ink market.

Furthermore, UV inks' versatility allows for their use in various industries, including food packaging, labels, and flexible packaging. This adaptability has increased demand for UV-curable inks within the flexographic printing market as companies seek efficient and reliable solutions for their printing needs. As a result, manufacturers have continued to invest in research and development further to enhance UV inks' performance and eco-friendly attributes, driving their popularity even higher.

The Growing Demand for Flexographic Inks

The growing demand for flexographic inks can be attributed to their ability to deliver exceptional print quality, efficiency, and cost-effectiveness across various packaging segments. As brand owners increasingly prioritize sustainable packaging solutions, there is a heightened interest in utilizing eco-friendly flexo ink technology that aligns with environmental goals while maintaining high-performance standards. This trend has fueled the expansion of the flexographic ink industry as manufacturers strive to meet evolving market demands with innovative solutions.

As the demand for flexographic inks continues to grow, manufacturers are also investing in research and development to create new formulations that offer improved adhesion, color vibrancy, and resistance to abrasion and fading. These advancements are essential for meeting the diverse needs of packaging applications in food and beverage, pharmaceuticals, and personal care products. By staying at the forefront of ink technology, companies can differentiate themselves in a competitive market while providing enhanced customer value.

Remember that using environmentally friendly materials such as water-based or UV-curable options can help your business stand out as a leader committed to sustainability within the flexible packaging industry!

The Benefits of Using Flexographic Inks

Environmental Advantages of Water-Based Inks

Due to their environmental and performance benefits, water-based flexographic inks are gaining traction in the printing industry. Here's why:

- Reduced VOC Emissions: Water-based inks contain minimal to no volatile organic compounds (VOCs), significantly reducing harmful air pollutants compared to traditional solvent-based inks. This makes them a more sustainable choice.

- Improved Print Quality: Water-based inks deliver vibrant and consistent color reproduction, producing high-quality printed materials.

- Enhanced Efficiency: Faster drying times increase printing speeds and overall production efficiency.

Water-based flexographic inks offer a compelling solution for the future of flexo printing by combining environmental responsibility with superior print quality and production speed.

Quality and Efficiency of Flexographic Printing

Flexographic printing inks are known for their exceptional print quality and efficiency, making them the preferred choice for various packaging applications. With advancements in UV inks for flexo printing, these inks offer superior adhesion and color vibrancy, resulting in high-quality printed materials that stand out on the shelf. Additionally, the quick-drying nature of UV inks enhances production efficiency, making flexographic printing a cost-effective option for businesses.

Flexographic printing inks are known for their exceptional print quality and efficiency and for their versatility. They can be used on a wide range of substrates, including paper, plastic, and film, making them suitable for various packaging applications. This versatility allows businesses to streamline their printing processes and reduce the need for multiple ink types, enhancing cost-effectiveness.

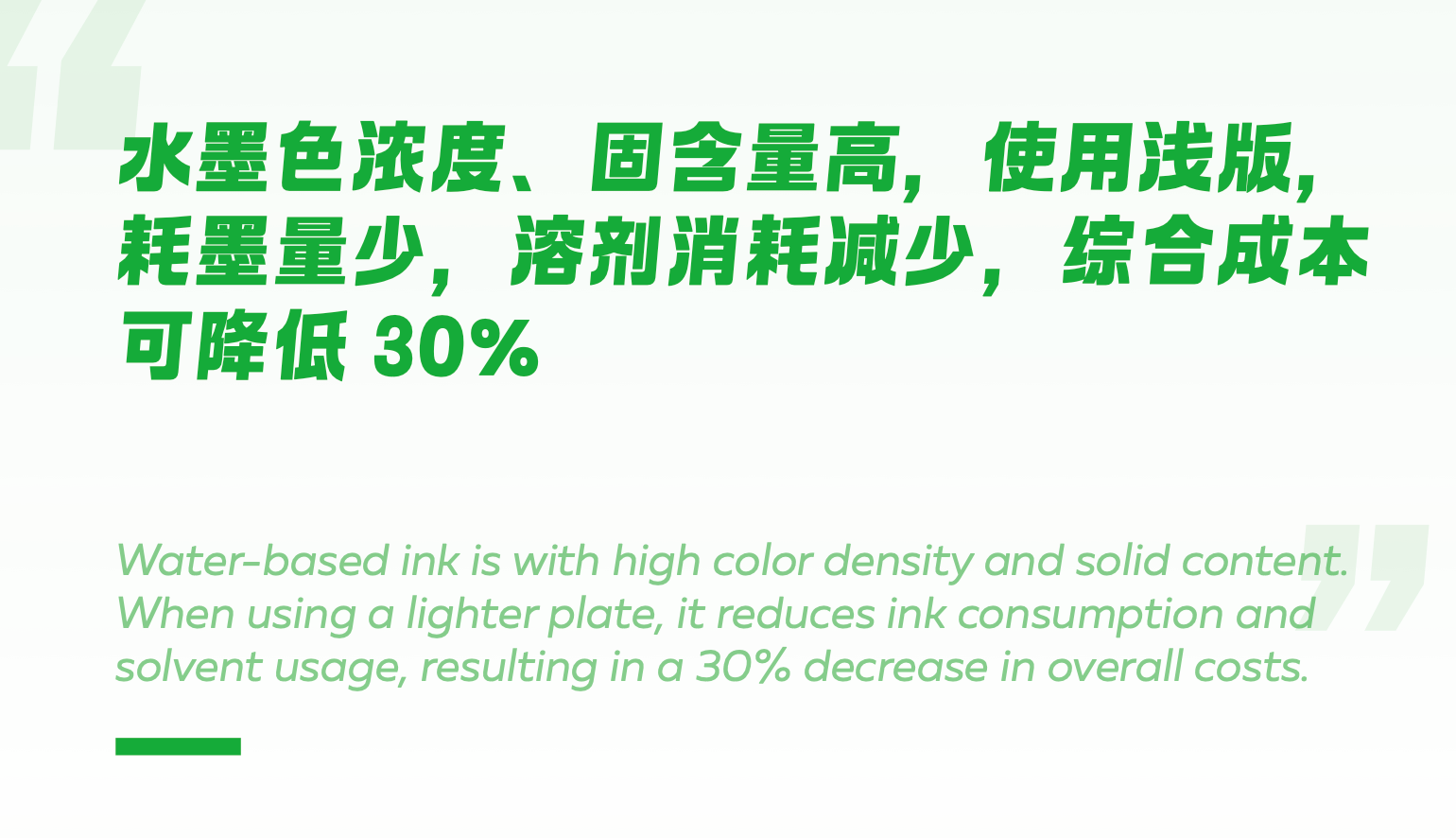

Cost-Effectiveness of Flexographic Inks

In addition to their environmental and quality benefits, flexographic printing inks offer significant cost advantages. The efficient use of ink and fast production speeds contribute to lower printing costs, making it an attractive option for businesses looking to maximize their return on investment. As a result, more companies are turning to flexo ink industry leaders like Qinghe Chemical for affordable yet high-quality water-based flexographic inks.

Furthermore, the cost-effectiveness of flexographic inks extends beyond just the initial printing process. Due to their fast-drying nature, these inks reduce the need for additional drying equipment and energy consumption, resulting in further cost savings for businesses. This makes flexographic printing an even more attractive option for companies looking to streamline their printing processes and reduce operational expenses.

Qinghe Chemical: Leading the Way in Flexographic Inks

Qinghe's Contribution to Sustainable Printing

Qinghe Chemical has been at the forefront of sustainable printing practices, revolutionizing the flexo ink industry with its eco-friendly solutions. Its commitment to reducing environmental impact through innovative flexographic printing inks sets it apart as a leader in the field.

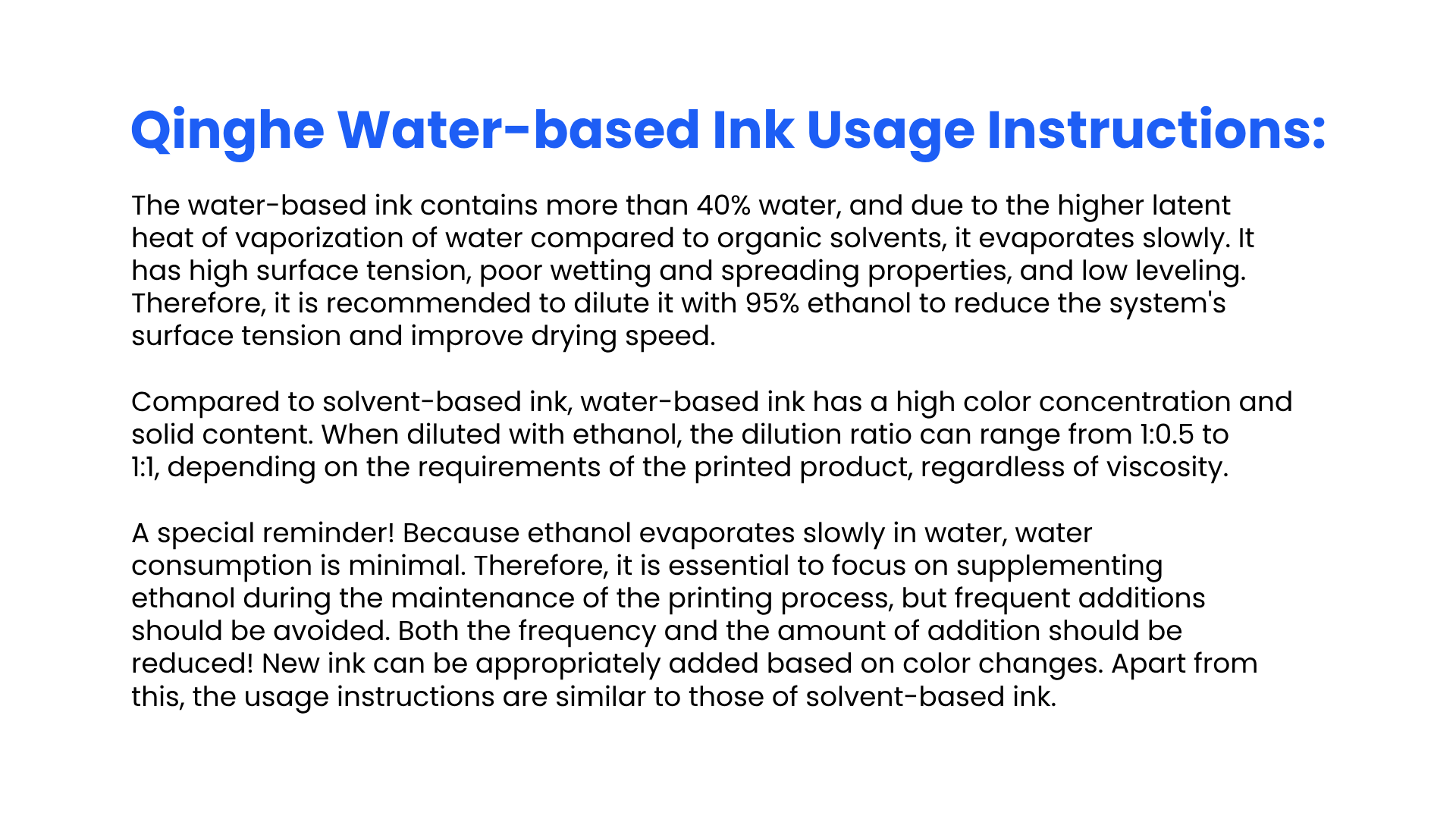

Qinghe Chemical's range of water-based flexographic inks has been a game-changer for the industry. By developing inks that are not only high-performing but also environmentally friendly, they have set a new standard for sustainable printing. Their commitment to innovation and sustainability has led to the widespread adoption of their products, proving that eco-friendly solutions can be both effective and profitable.

Qinghe's Range of Water-Based Flexographic Inks

As one of the top flexographic ink suppliers, Qinghe Chemical offers a diverse range of water-based ink for flexo printing. Their UV inks are known for their high quality and performance, catering to the evolving needs of the industry and ensuring superior results for their clients.

Qinghe Chemical is dedicated to providing eco-friendly printing solutions, and its water-based flexographic inks are a testament to this commitment. By offering a diverse range of water-based inks for flexo printing, it enables its clients to embrace sustainable practices without sacrificing quality or performance. With Qinghe's UV inks for flexo printing, businesses can achieve superior results while reducing their environmental impact, making it a win-win for the industry and the planet.

Qinghe's Commitment to Eco-Friendly Printing Solutions

Qinghe Chemical is dedicated to providing eco-friendly flexographic ink solutions that meet and exceed industry standards. Their continuous research and development efforts have led to a range of water-based inks for flexo printing that are both sustainable and high-performing, making them a trusted choice for environmentally conscious businesses.

The Future of the Flexographic Ink Industry

Trends in Flexographic Printing Technology

The future of the flexo ink industry is set to be shaped by exciting advancements in flexographic printing technology. With the increasing demand for sustainable printing solutions, there is a growing focus on developing more efficient and eco-friendly flexographic printing presses. These presses are designed to minimize waste and reduce environmental impact while delivering high-quality prints, making them a game-changer in the industry.

Innovations in Flexographic Ink Manufacturing

Innovations in flexographic ink manufacturing are revolutionizing the industry, with a strong emphasis on developing UV inks for flexo printing that are both environmentally friendly and high-performing. These UV inks offer faster curing times, improved adhesion, and enhanced durability, making them an attractive option for printers looking to elevate their print quality while reducing their ecological footprint.

Sustainable Practices in the Flexographic Printing Industry

The future of the flexo ink industry is undoubtedly leaning towards sustainable practices, with an increasing number of flexographic ink suppliers and manufacturers prioritizing eco-friendly solutions. From water-based ink for flexo printing to bio-based alternatives, the industry is witnessing a shift towards sustainable raw materials and manufacturing processes that aim to minimize environmental impact without compromising print quality.

Embrace Sustainable Flexographic Printing with Qinghe Chemical

In conclusion, the flexographic ink industry has seen remarkable growth and innovation, particularly in developing water-based and UV inks for flexo printing. As the demand for sustainable printing solutions continues to rise, flexographic ink suppliers and manufacturers are crucial in driving eco-friendly practices. Qinghe Chemical stands at the forefront of this movement, offering a wide range of water-based flexographic inks that deliver exceptional quality and minimize environmental impact.

Qinghe Chemical's commitment to sustainable printing solutions sets a new standard for the flexo ink industry. Focusing on developing water-based ink for flexo printing, they have revolutionized the. By embracing eco-friendly products, businesses can significantly reduce their carbon footprint while delivering outstanding print results.

Advantages of Using Water-Based Inks in Flexographic Printing

Due to their environmental and performance benefits, water-based inks are gaining traction in flexographic printing. Here's why:

- Eco-Friendly: Water-based inks contain minimal to no VOCs (Volatile Organic Compounds), significantly reducing air pollution and creating a safer work environment.

- Superior Print Quality: These inks can achieve excellent color reproduction and sharp images, rivaling solvent-based options.

- Reduced Hazardous Waste: Water-based inks are easier to clean up and dispose of than solvent-based inks, minimizing hazardous waste.

As sustainability becomes a growing concern, water-based inks offer a compelling solution for flexographic printers seeking to minimize their environmental impact while maintaining high-quality printing results.

The Growing Importance of Eco-Friendly Flexographic Inks

As sustainability becomes a top priority for businesses across all industries, the demand for eco-friendly flexographic printing inks continues to grow. This shift is driven by consumer awareness and regulatory pressures to reduce environmental impact. Flexographic ink manufacturers respond to this demand by investing in innovative technologies that prioritize sustainability without compromising performance.

With Qinghe Chemical leading the way and an increasing focus on eco-friendly practices within the industry, it's clear that sustainable solutions will define the future of flexographic printing. By embracing water-based inks and prioritizing environmental responsibility, businesses can meet consumer expectations and contribute to a greener planet through their printing processes.