Introduction

Ink is crucial for environmental and performance reasons when printing on plastic. Water-based ink has gained popularity for its eco-friendly properties and high-quality results. As a leading innovator in this field, Qinghe Chemical is revolutionizing water-based inks, offering sustainable solutions for plastic printing needs.

Understanding the Basics of Water-based Ink

Water-based ink offers a sustainable and efficient alternative to traditional inks. Here's why:

- Environmentally Friendly: Water-based ink uses water instead of harsh chemicals as a solvent, minimizing environmental impact and reducing exposure to harmful toxins.

- Reduced Emissions: The water-based composition produces fewer harmful emissions during printing, improving air quality.

- Faster Drying Times: Shorter drying times improve printing efficiency, leading to quicker project turnaround times for businesses with tight deadlines.

- Vibrant and Long-lasting Prints: Water-based ink produces high-quality prints with vivid colors that remain durable on various substrates.

Water-based ink provides a winning combination of environmental responsibility, printing efficiency, and superior print quality, making it a valuable choice for businesses and the environment.

The Environmental Impact of Choosing the Right Ink

Regarding plastic printing, ink selection plays a crucial role in environmental impact. Here's why water-based inks are a more sustainable choice:

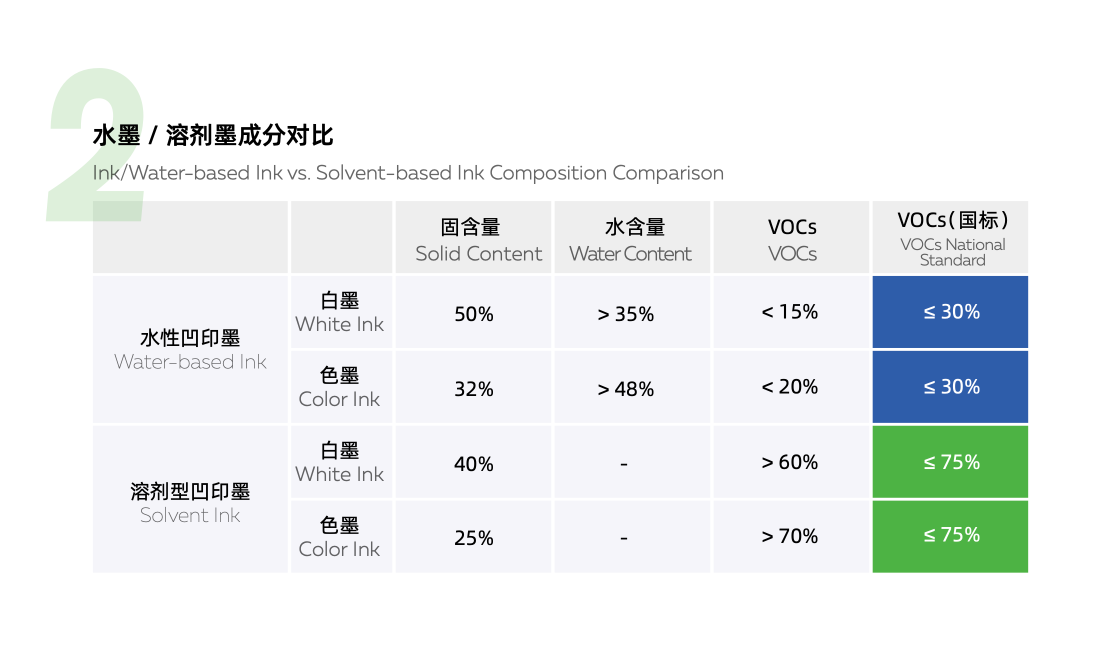

- Reduced Air Pollution: Water-based inks contain lower volatile organic compounds (VOCs) levels than traditional solvent-based inks. This significantly reduces their contribution to air pollution and creates a healthier environment.

- Improved Sustainability: Water-based inks are more accessible to recycle than solvent-based inks, minimizing waste and promoting a more sustainable printing process.

- Enhanced Worker Safety: With fewer hazardous chemicals, water-based inks create a safer work environment for printing personnel, reducing the risk of exposure to harmful substances. This fosters a healthier workforce and contributes to a more responsible business operation.

Plastic printers can minimize their environmental footprint by choosing water-based inks, ensuring worker well-being, and demonstrating a commitment to sustainable practices.

How Qinghe Chemical is Revolutionizing Water-based Inks

Qinghe Chemical has been at the forefront of developing innovative water-based ink solutions for plastic printing applications. Focusing on environmental responsibility and product excellence, they have created a diverse range of high-performance inks that meet the stringent requirements of modern printing processes while prioritizing sustainability.

In addition to their commitment to sustainability, Qinghe Chemical's water-based inks offer a range of benefits for plastic printing applications. These inks provide excellent adhesion and durability, ensuring printed designs remain vibrant and intact even after prolonged use. Furthermore, their water-based nature makes them easy to clean up and reduces the emission of volatile organic compounds, contributing to a healthier work environment.

Benefits of Using Water-based Ink

Water-based ink offers numerous benefits, making it an attractive choice for plastic printing ink. One of the most significant advantages is its reduced environmental footprint. Unlike traditional solvent-based inks, water-based inks have lower volatile organic compound (VOC) emissions, making them more eco-friendly for recycling plastic printing ink. This means choosing water-based ink can help reduce air pollution and minimize environmental harm.

Reduced Environmental Footprint

By using water-based ink for plastic bags and other plastic film printing applications, businesses can demonstrate their commitment to sustainability and environmental responsibility. With increasing consumer demand for eco-friendly products, using water-based ink allows companies to align with these values and enhance their brand image as environmentally conscious organizations.

Health and Safety Benefits

Water-based inks offer several advantages over traditional solvent-based inks, particularly for plastic film printing with acrylic ink on plastic. Here's why:

- Safer Work Environment: Water-based inks are non-toxic and don't emit harmful fumes, reducing employee health risks.

- Easier Cleanup and Maintenance: These inks clean up with water, requiring less effort and harsh chemicals than solvent-based inks.

- Environmentally Friendly: Water-based solutions minimize the use of hazardous chemicals, contributing to a greener workplace.

- Reduced Insurance Costs: The lower fire risk associated with water-based inks can lead to lower insurance premiums.

By switching to water-based inks, plastic film printers can promote worker safety, simplify cleanup processes, and contribute to a more sustainable printing environment.

Cost Savings and Efficiency

In addition to its environmental and health benefits, water-based ink offers businesses cost savings and efficiency advantages. While the initial investment in water-based ink may be slightly higher than solvent-based alternatives, the long-term savings from reduced waste disposal costs, lower energy consumption, and improved equipment maintenance make it a financially savvy choice for plastic printing applications.

Now that we've explored the benefits of using water-based ink for plastic film printing, let's delve into essential factors to consider when choosing this sustainable solution.

Factors to Consider When Choosing Water-based Ink

Compatibility with Plastic Films

When choosing water-based ink for plastic printing, it's crucial to consider its compatibility with various types of plastic films. Qinghe Chemical offers a diverse range of water-based inks formulated explicitly for different plastic materials, ensuring optimal adhesion and durability. Whether you're printing on polyethylene, polypropylene, or PVC, our inks are designed to deliver vibrant and long-lasting results on any plastic surface.

As we continue to prioritize sustainability, our water-based inks are also designed with recyclability in mind. Using water as the primary solvent, our inks minimize environmental impact and make it easier to recycle printed plastic materials. This benefits the environment and aligns with the growing demand for eco-friendly printing solutions. With Qinghe Chemical's water-based inks, you can achieve high-quality results while reducing your carbon footprint.

Recyclability and Sustainability

One of the key advantages of water-based ink for plastic printing is its recyclability and sustainability. Unlike solvent-based inks that contribute to environmental pollution, water-based inks can be easily recycled and are less harmful to the environment. By choosing Qinghe Chemical's water-based inks, you're making a sustainable choice that aligns with your commitment to eco-friendly practices and reduces your carbon footprint.

Furthermore, water-based inks are non-toxic and pose fewer safety concerns than solvent-based ones. This makes them a safer option for workers who handle the printing process, reducing the risk of exposure to harmful chemicals. By prioritizing using water-based inks, you create a safer working environment for your employees and contribute to overall workplace well-being.

Toxicity and Safety Concerns

Many businesses are concerned about the potential toxicity of printer ink when used on plastic surfaces, particularly regarding food packaging applications. With Qinghe Chemical's water-based inks, you can rest assured that our products are non-toxic and comply with stringent safety regulations. Our inks are free from harmful chemicals such as lead and heavy metals, making them safe for plastic bags, food packaging, and other consumer products.

In addition to being non-toxic and safe for use on plastic surfaces, Qinghe Chemical's water-based inks also offer excellent adhesion and durability. This means your printed materials will maintain their vibrant colors and high-quality appearance, even when exposed to various environmental conditions. Whether it's for food packaging, retail bags, or other consumer products, our inks provide long-lasting performance that meets the demands of modern businesses.

Now that we've explored the factors to consider when choosing water-based ink for plastic printing, let's delve into how Qinghe Chemical's innovative solutions can meet your needs and contribute to a more sustainable future.

Qinghe Chemical's Water-based Ink Solutions

Diverse Range of Products

At Qinghe Chemical, we offer a diverse range of water-based inks specifically designed for plastic printing. Our innovative formulations cater to various printing requirements, including vibrant color options, fast-drying properties, and excellent adhesion to plastic surfaces.

Expertise in Plastic Film Printing

With years of experience in the industry, Qinghe Chemical has established itself as a leader in plastic film printing ink. Our team of experts understands the unique challenges and intricacies of printing on plastic substrates, ensuring optimal ink performance and print quality.

Commitment to Environmental Responsibility

As a company dedicated to environmental responsibility, we prioritize sustainability in our ink production processes. Our water-based inks are free from harmful chemicals and toxins, offering a safer and greener alternative to plastic film printing. We also actively promote printer ink recycling initiatives to minimize waste and reduce environmental impact.

Remember that choosing the right ink for plastic film printing is crucial for achieving high-quality results while minimizing environmental impact. With Qinghe Chemical's diverse range of water-based ink products, expertise in plastic film printing, and commitment to environmental responsibility, you can confidently make the eco-friendly choice for your printing needs.

Common Misconceptions About Water-based Inks

Dispelling Myths About Performance

One common misconception about water-based inks is that they don't perform as well as solvent-based inks. However, with technological advancements, water-based inks offer excellent adhesion, durability, and fast drying times, making them a reliable choice for various printing applications. Water-based inks can deliver high-quality results without compromising performance, Whether for packaging, labels, or promotional materials.

Addressing Concerns About Color Quality

Some may worry that using water-based inks on plastic surfaces will result in dull or less vibrant colors. The truth is that modern water-based ink formulations can produce vivid and eye-catching colors on plastic films and bags. With the right expertise and ink solutions from Qinghe Chemical, you can achieve the desired color quality while prioritizing environmental sustainability.

Debunking Myths About Application Techniques

Another misconception is that applying water-based ink on plastic requires specialized equipment or complicated processes. In reality, many modern printers are equipped to efficiently handle water-based inks, making the transition from solvent-based to water-based printing relatively seamless. You can successfully debunk any myths about application techniques by working with Qinghe Chemical's experts and utilizing their range of ink solutions designed for plastic film printing.

Now that we've dispelled some common misconceptions about water-based inks and highlighted their benefits for plastic film printing let's explore how you can make the right choice for your specific printing needs.

Making the Right Choice for Your Printing Needs

When evaluating your specific requirements for plastic printing ink, consider the type of plastic film you will use, the desired color vibrancy, and the intended application method. Understanding these details will help you select the most suitable ink for your needs.

Evaluating Your Specific Requirements

Before choosing plastic ink for your printing needs, consider whether you require ink compatible with various plastic films commonly used in packaging and labeling. Additionally, assess whether you need ink that can be easily recycled to align with sustainability goals.

Consultation with Qinghe Chemical Experts

Consulting with Qinghe Chemical experts can provide valuable insights into selecting the correct ink for your specific printing requirements. Their expertise in plastic film printing and commitment to environmental responsibility make them a trusted partner in guiding you toward sustainable and practical solutions.

Tips for Successful Implementation

To ensure the successful implementation of plastic ink in your printing processes, consider factors such as proper storage and handling to maintain its quality. Additionally, follow manufacturer recommendations for application techniques to achieve optimal results.

Qinghe Chemical: Your Partner for Environmentally Responsible Inks

Choosing the right plastic ink is crucial when it comes to making an informed decision about eco-friendly printing. With Qinghe Chemical's sustainable solutions for plastic film printing, you can ensure that your printing needs are met without compromising environmental responsibility. Trust Qinghe Chemical as your partner for environmentally responsible inks.

Making an Informed Decision for Eco-friendly Printing

By understanding the impact of printer ink recycling and the importance of using plastic printing ink, you can make a conscious choice for eco-friendly printing. With Qinghe Chemical's expertise in acrylic ink on plastic, you can rest assured that your printing processes are environmentally responsible and sustainable.

Choosing Sustainable Solutions for Plastic Film Printing

Qinghe Chemical offers diverse ink solutions specifically designed for plastic film printing. Focusing on recyclability and sustainability, their products help reduce the environmental footprint while delivering high-quality results.

Trust Qinghe Chemical as your partner when choosing environmentally responsible inks for all your plastic film printing needs. Their commitment to sustainability and expertise in acrylic ink on plastic makes them the ideal choice for eco-conscious businesses.