Introduction

Water-based inks are becoming increasingly popular in screen printing due to their numerous advantages. Not only are they environmentally friendly, but they also offer significant health benefits for both processors and end users. As a leading supplier of water-based inks for screen printing, Qinghe Chemical is at the forefront of providing sustainable and safe printing solutions.

The Advantages of Water-Based Inks

Water-based inks are famous for screen printing due to several advantages, making them ideal for eco-conscious printers and applications requiring a soft feel. Here are some of the key benefits of using water-based inks:

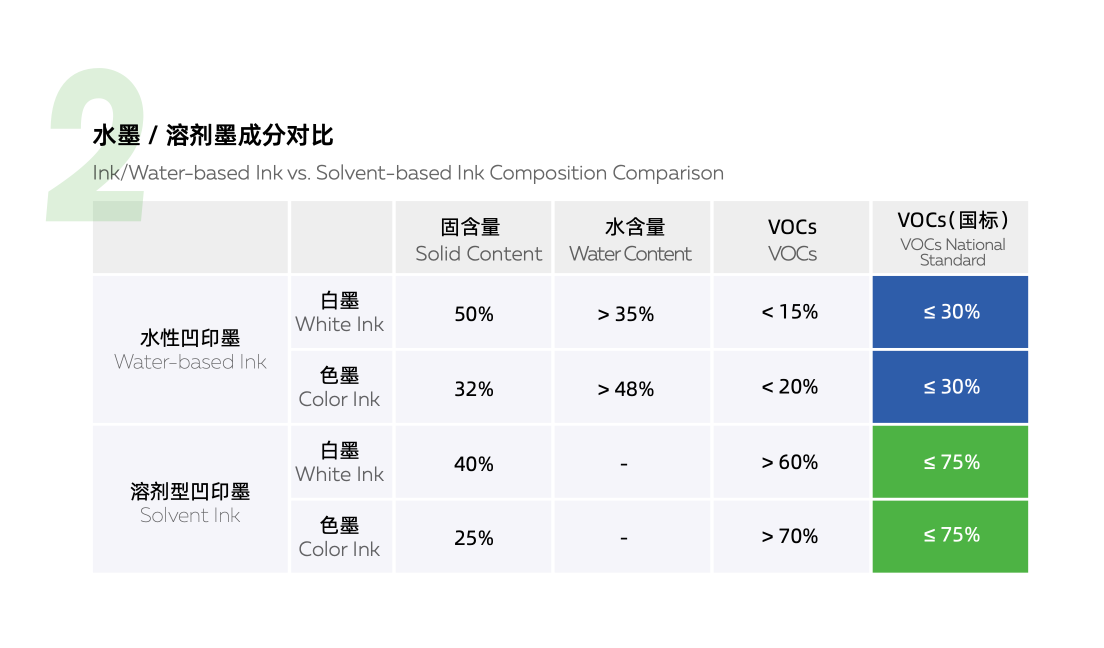

- Eco-friendly: Water-based inks have low VOC (volatile organic compound) emissions, reducing their impact on air quality and the environment compared to solvent-based inks. This makes them a more sustainable choice for screen printing.

- Soft Hand: Water-based inks penetrate the fabric, resulting in a smoother, more breathable print that feels lighter than plastisol. This is ideal for garments and applications where comfort is essential.

- Versatility: Water-based inks, including flexible food packaging, can be used on various substrates. They offer excellent performance and adhesion on multiple materials, making them versatile for different projects.

- Wash Durability: When properly cured, water-based inks can be as durable as plastisol inks and withstand multiple washes without cracking or fading.

- Vibrant Colors: Water-based inks can produce a wide range of vibrant colors, making them suitable for creating eye-catching designs.

Water-based inks offer a sustainable, versatile, and comfortable alternative to traditional plastisol inks for screen printing projects.

Environmental Impact of Water-Based Inks

In the printing industry, reducing environmental impact is becoming increasingly important. Water-based inks offer a more sustainable solution compared to traditional solvent-based inks. Here's how:

- Reduced VOC Emissions: Water-based inks contain minimal to no Volatile Organic Compounds (VOCs). These chemicals, released during printing with solvent-based inks, contribute to air pollution and pose health risks. By switching to water-based inks, printing companies can significantly improve air quality and create a healthier environment.

- Lower Environmental Footprint: Water-based inks are generally biodegradable, breaking down naturally over time. This minimizes waste accumulation in landfills and reduces the overall environmental impact of the printing process.

- Improved Worker Health: Unlike solvent-based inks, water-based inks don't release harmful chemicals. This creates a safer work environment for printing professionals, reducing the risk of respiratory problems and other health issues. This leads to a healthier workforce and potentially higher productivity.

Water-based inks offer a win-win situation for the environment and the printing industry workforce. Their adoption is a significant step towards more sustainable printing practices.

Health Benefits of Water-Based Inks

Not only are water-based inks better for the environment, but they also offer notable health benefits. Processors working with these inks experience improved health due to reduced exposure to harmful chemicals commonly found in solvent-based inks. Safer printing, transportation, and storage make water-based inks an ideal choice for those prioritizing health and safety.

In addition to the health benefits for processors, water-based inks contribute to a healthier end product. These inks do not release volatile organic compounds (VOCs) into the air during printing, which means that the final printed materials are safer for consumers to handle and use. This is especially important for items like clothing and packaging that come into direct contact with skin or food. Businesses can demonstrate their commitment to producing safe and eco-friendly products by choosing water-based inks.

Cost Savings

One major advantage of using water-based inks for screen printing is the significant cost savings that can be achieved. With a reduced need for exhaust air treatment, businesses can save on expensive ventilation systems and ongoing maintenance costs. This reduces operational expenses and contributes to a more sustainable and eco-friendly printing process.

Reduced Need for Exhaust Air Treatment

Water-based inks are known for their low VOC emissions, meaning costly exhaust air treatment systems are less needed. This saves money on initial installation and reduces ongoing energy and maintenance costs. Businesses can enjoy these cost savings by choosing the best water-based ink for screen printing while minimizing their environmental impact.

Furthermore, water-based inks are easier to clean up, reducing the need for harsh chemicals and solvents. This creates a safer work environment for employees and eliminates the need for costly fire protection measures. By minimizing flammable materials, businesses can save on insurance premiums and avoid the expenses associated with fire safety compliance.

Elimination of Costly Fire Protection Measures

Another significant cost-saving benefit of using water-based inks for screen printing is the elimination of costly fire protection measures required with solvent-based inks. Water-based inks are non-flammable, reducing the need for expensive fire protection equipment and safety measures. This saves money and creates a safer working environment for employees.

Furthermore, eliminating fire protection measures means less paperwork and administrative burden for businesses. With water-based inks, there is no need to constantly update safety protocols and maintain fire safety equipment, allowing companies to focus on their core operations without being bogged down by unnecessary regulatory requirements. This streamlining of processes can lead to increased productivity and efficiency in the workplace.

Environmental Friendliness

Low VOC Emissions

Water-based inks for screen printing are known for their low VOC emissions, making them a more environmentally friendly option compared to solvent-based inks. With minimal volatile organic compound emissions, these inks contribute to better air quality and reduce the risk of respiratory issues for workers and nearby communities. Choosing water-based inks benefits your business and the environment.

Due to their biodegradable nature, water-based inks also have a reduced environmental impact. Unlike solvent-based inks, water-based inks break down more efficiently, reducing the long-term ecological effects. This means businesses using these inks can feel good about contributing to sustainability and waste reduction. Additionally, the use of water-based inks can help companies align with eco-friendly initiatives and enhance their brand image as environmentally responsible.

Reduced Impact on the Environment

When it comes to environmental impact, water-based inks are the best choice for screen printing. These inks have a reduced impact on the environment due to their eco-friendly composition, which minimizes harm to ecosystems and wildlife. By opting for water-based inks, you can demonstrate your commitment to sustainability and responsible business practices.

In addition to their reduced impact on the environment, water-based inks also offer superior breathability and comfort when used in textile printing. Unlike traditional plastisol inks, water-based inks allow the fabric to retain its natural feel and texture, making them ideal for high-quality, soft-to-the-touch prints. This added benefit enhances the overall product quality and contributes to a more sustainable and eco-friendly end product.

Health and Safety

Improved Health for Processors

Water-based inks for screen printing offer improved health benefits for processors, as they contain fewer harmful chemicals than solvent-based inks. This means reduced exposure to toxic fumes and a healthier working environment for those involved in the printing process.

Furthermore, water-based inks are more accessible and safer to transport and store than solvent-based inks. This is because they do not pose the same risk of flammability or toxicity, making them a more convenient option for processors to handle. The reduced risk of spills or accidents during transportation and storage also contributes to a safer overall working environment.

Safer Printing, Transportation, and Storage

When it comes to safety, water-based inks are the best choice for screen printing. Unlike solvent-based inks, water-based inks are non-flammable and do not pose a fire hazard during printing, transportation, or storage. This eliminates costly fire protection measures and ensures a safer overall process.

Furthermore, water-based inks offer the advantage of being more versatile than solvent-based inks. They can be used on a variety of materials, including paper, fabric, and wood, making them a great choice for a wide range of printing projects. This versatility allows for greater creativity and innovation in design and the ability to cater to diverse client needs.

Versatility

Water-based inks for screen printing offer a wide range of applications, making them suitable for various substrates such as paper, cardboard, and fabric. Whether for t-shirts, posters, or packaging materials, these inks provide vibrant and long-lasting colors that meet the demands of different industries.

Wide Range of Applications

Water-based ink is the best for screen printing on various surfaces, such as cotton, polyester, and blends. These inks are ideal for creating soft and breathable prints on fabrics, making them a popular choice for apparel brands looking to achieve a high-quality finish while being eco-friendly.

Excellent Performance on Flexible Food Packaging

When it comes to flexible food packaging, water-based screen printing ink excels at providing safe and non-toxic solutions. These inks comply with food safety regulations and offer excellent adhesion to ensure the packaging maintains its integrity throughout its shelf life.

Furthermore, water-based screen printing ink offers a wide range of vibrant and long-lasting colors, making it an ideal choice for flexible food packaging that needs to stand out on the shelf. The versatility of these inks allows for intricate designs and detailed images to be printed onto packaging materials, enhancing the product's visual appeal. This can be especially advantageous for brands looking to differentiate themselves in a competitive market.

Quality and Performance

When it comes to quality and performance, water-based inks for screen printing are second to none. They offer comparable quality to solvent-based inks, providing vibrant and long-lasting results on various substrates. Whether you're printing on fabric, paper, or cardboard, water-based inks deliver exceptional color intensity and sharpness, making them the best water-based ink for screen printing.

Comparable Quality to Solvent-Based Inks

Water-based inks for screen printing have revolutionized the industry with their ability to match the quality of solvent-based inks. Their pigments penetrate the fabric or substrate deeply, resulting in bright and durable prints that maintain their vibrancy wash after wash. This makes them the top choice for environmentally conscious printers who refuse to compromise on quality.

Water-based inks also offer the advantage of producing permanent and waterproof results. This means that prints created with water-based inks are more resistant to fading, smudging, or running when exposed to moisture. Whether it's a rainy day or a trip through the washing machine, prints made with water-based inks will stay vibrant and intact, ensuring that your designs remain sharp and professional for the long haul.

Permanent and Waterproof Results

One of the most common questions about water-based inks is whether they are waterproof and permanent. The answer is a resounding yes! These inks create permanent prints that withstand regular washing without fading or bleeding. Additionally, they offer excellent resistance to water, making them ideal for outdoor applications such as banners and signage.

Furthermore, water-based inks are not only waterproof and permanent but also offer a more environmentally friendly option compared to traditional solvent-based inks. With lower levels of volatile organic compounds (VOCs), these inks contribute to cleaner air and reduced environmental impact. This makes them a top choice for businesses looking to reduce their carbon footprint while achieving vibrant and long-lasting prints.

More businesses are turning to water-based screen printing ink suppliers like Qinghe Chemical for sustainable printing solutions. With their unmatched quality and performance, these eco-friendly inks are setting a new standard for the industry while delivering outstanding results across a wide range of applications.

Sustainable Printing Solutions with Water Based Inks

Water-based inks for screen printing have emerged as the top choice for sustainable printing solutions. With their reduced environmental impact and health benefits, they offer a safer and greener alternative to traditional solvent-based inks. The best water-based ink for screen printing is not only versatile but also provides excellent performance on flexible food packaging, making it a go-to option for various applications.

Water-based inks lead the way in sustainable printing solutions, offering a greener alternative to traditional solvent-based inks. Their low VOC emissions and reduced environmental impact make them the top choice for eco-conscious businesses looking to minimize their carbon footprint. With water-based screen printing ink suppliers like Qinghe Chemical paving the way, switching to environmentally friendly printing solutions is easier than ever.

Improved Safety and Health Benefits

Water-based inks offer a significant advantage over solvent-based inks: improved safety and health benefits. Here are some reasons why:

- Non-toxic: Unlike solvent-based inks, which can contain harmful chemicals, water-based inks are formulated with minimal to no volatile organic compounds (VOCs). This makes them much safer for everyone involved in printing, from processors and printers to those handling transportation and storage.

- Reduced health risks: By eliminating exposure to harsh chemicals, water-based inks can help reduce the risk of respiratory problems, skin irritation, and other health complications often associated with solvent-based inks.

- Safer work environment: Because water-based inks are less hazardous, they provide a safer working environment for printing professionals. This reduces the need for extensive safety gear and improves workplace air quality.

Water-based inks provide a more sustainable and healthy alternative to traditional solvent-based inks. Their non-toxic properties benefit both workers and the environment, making them a preferable choice for various printing applications.

Qinghe Chemical Leading the Way in Green Printing Solutions

As a leading supplier of water-based inks for screen printing, Qinghe Chemical is at the forefront of green printing solutions. Their commitment to providing high-quality, non-toxic, water-based inks has made them a trusted partner for businesses looking to reduce their environmental impact without compromising performance. With its dedication to innovation and sustainability, Qinghe Chemical continues to lead the way toward a more eco-friendly future.